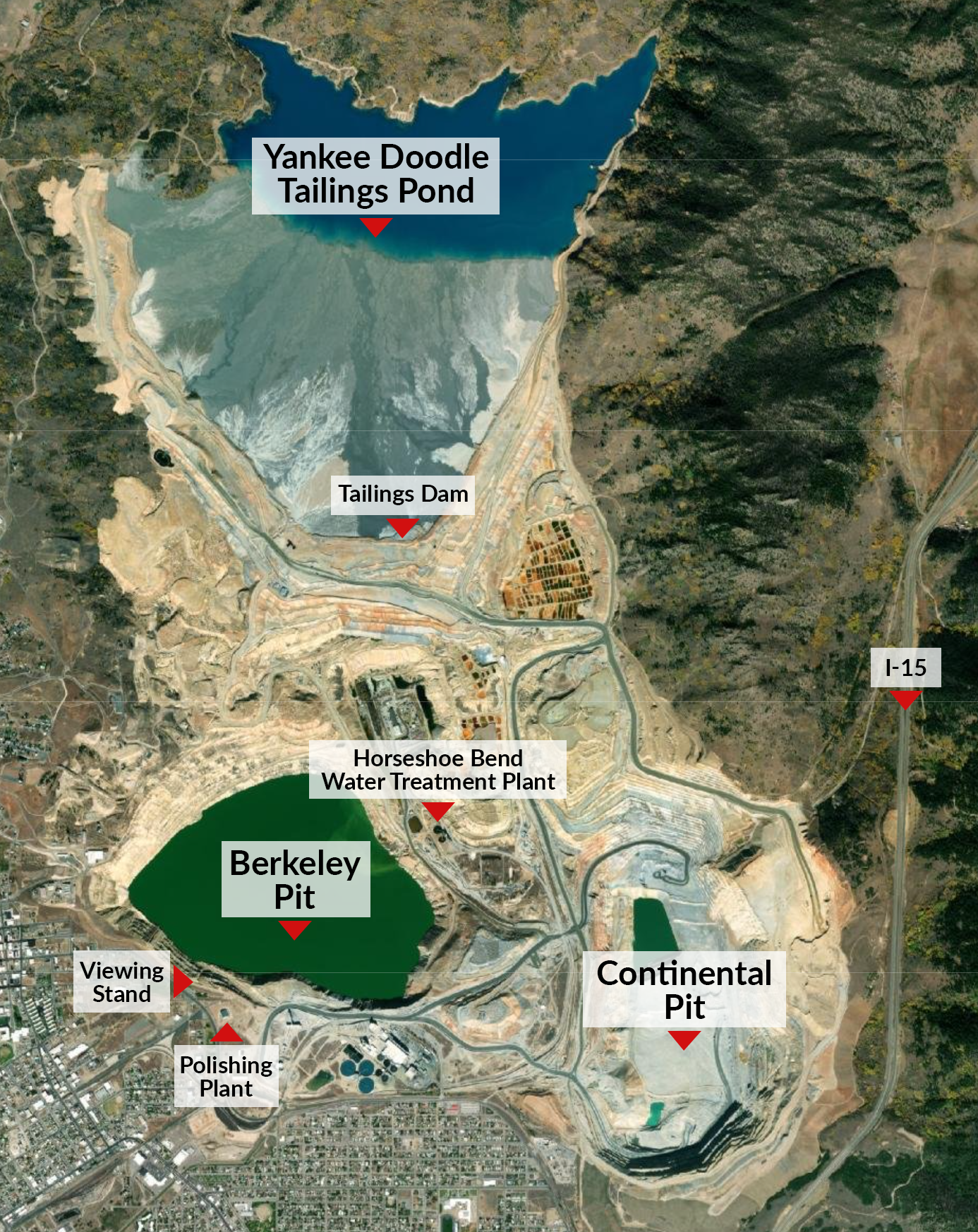

The Berkeley Pit is the primary feature of a larger Superfund operable unit called the Butte Mine Flooding Operable Unit, or BMFOU for short. The Record of Decision for the BMFOU requires water treatment and water level control to keep the Berkeley Pit and associated points of compliance below the protective water level (PWL). In order to do this, contaminated water from the Berkeley Pit and other sources is collected and treated for either offsite discharge, or onsite inclusion in MR’s active mining operation.

The water management and treatment process for the site can be summarized into three steps:

-

First pH adjustment – The heavy metals of the acidic waters are removed by increasing the pH of the water to varying levels. These pH adjustments allow metals to precipitate out.

-

Next, metals precipitation – Adequate residence time (i.e. time for particulate settlement) is needed to allow the precipitation process to occur. This is completed by using large vessels known as clarifiers within a water treatment facility; or by utilizing large bodies of water (e.g., the Yankee Doodle Tailings Impoundment).

- Finally, recirculate or discharge – Treated waters are circulated back into the active mining circuit or put through a final treatment system for offsite discharge. This final treatment step before discharge is often referred to as polishing.

Site Treatment Options and Flexibility

The site has two primary treatment systems. The first is known as the Horseshoe Bend Water Treatment Plant, and the second is the Horseshoe Bend Capture System. Both systems utilize lime to adjust the pH and precipitate metals from the water, and together offer water treatment flexibility With the introduction of the Horseshoe Bend Capture System in 2019, the site currently has two redundant water treatment systems capable of meeting all current anticipated treatment demand and controlling the Berkeley Pit groundwater system.

The Horseshoe Bend Water Treatment Plant was brought online in 2003 to treat surface water flowing from the Horseshoe Bend Seeps preventing it from flowing into the Berkeley Pit. The plant is designed to treat up to 7 million gallons of water per day.

A treatment pond (i.e., clarifier) at the Horseshoe Bend Water Treatment Plant.

The Horseshoe Bend Capture System was brought online in 2019 as part of the Berkeley Pit and Discharge Pilot Project, often referred to as the Pilot Project for short. The Pilot Project provided the site with additional water treatment flexibility. The Horseshoe Bend Capture System utilizes the active mining processes at Montana Resources for both pH adjustment and metals precipitation. This is done by incorporating metals-laden, acidic water and lime into a slurry mix within liquified tailings being transported for disposal[CJ4] [RK5] in the existing mine tailings storage facility. The tailings disposal facility, known as the Yankee Doodle Tailings Impoundment, is utilized as a treatment step for the residence time needed to precipitate and settle out the metal contaminants.

Berkeley Pit and Discharge Pilot Project

Prior to 2019, Berkeley Pit water had never been pumped from the Berkeley Pit for treatment, nor had the treated waters been discharged offsite. Starting in late 2019, Atlantic Richfield and Montana Resources initiated the Berkeley Pit and Discharge Pilot Project (Pilot Project). The Pilot Project was designed to test the ability of treatment technology and methods to manage and treat Berkeley Pit water and meet water quality standards to discharge treated water off the site.

The Pilot Project is currently evaluating the effectiveness of controlling the rise of Berkeley Pit water levels and additional methods of treating water that meet water quality standards for Silver Bow Creek established in the 2002 Consent Decree. The results of this Pilot Project evaluation will help inform the final water management and treatment process for the Butte Mine Flooding Operable Unit.

Since 2019, water has been pumped from the Berkeley Pit for treatment at the Horseshoe Bend Treatment Plant and/or Horseshoe Bend Capture System. As a result, the water levels in the Berkeley Pit and the 14 points of compliance have remained stable. This is evidence that the points of compliance are connected to the water level within the Berkeley Pit, and that pumping and treating water from the Pit and releasing it offsite will ensure the Protective Water Level will not be reached.

Compliance points around the Berkeley Pit.

How is the water treated?

Raising the pH

The primary approach to remove metals from the Berkeley Pit and other site-contaminated acidic waters is to raise the water’s pH. At different pH levels, different metals precipitate, or form solids and drop out of the water. A lime treatment system is used to change pH levels. Lime has a pH of approximately 12.5 and by adding this substance, the pH of Berkeley Pit water is increased in order to precipitate out metals.

Metals Precipitation

Once the pH of the Berkeley Pit and other site-contaminated waters is raised, time is needed for the formerly dissolved metals to precipitate and settle out. This process is commonly referred to as retention time. The site’s two treatment systems have two very different methods for providing this retention time and metals removal.

- The Horseshoe Bend Water Treatment Plant provides this retention time in the form of large vessels called clarifiers. The lime treated water is held in clarifiers to allow the metals to settle out. This process results in a substance called sludge, which is then disposed of back in the Berkeley Pit.

- The Horseshoe Bend Capture System provides retention time by utilizing the Yankee Doodle Tailings Impoundment’s pond. The pH adjusted water is retained within the Yankee Doodle Tailings Impoundment to allow the metals to precipitate and settle out.

The water contained in the Yankee Doodle Tailings Impoundment supports Montana Resource’s active mining activities. For example, the water from the impoundment flows by gravity to the mine’s concentrator where it is incorporated into the milling and concentrating process. If the treated water is not necessary in mining operations, the water may be routed to a secondary water treatment called the Polishing Facility where further treatment occurs.

An aerial view of the Berkeley Pit and important surrounding locations.

Polishing Facility

The initial treatment of contaminated water on the site is to raise the pH of the water and precipitate out metal contaminants. Once the metals have been removed, the water still requires a final treatment step often referred to as polishing before it can meet compliance standards to be discharged offsite. The term “polishing” refers to the final effort to make the water free from imperfections. As part of the Pilot Project, a secondary water treatment plant known as the Polishing Facility was constructed for this purpose.

The Polishing Facility currently uses a two-stage filtration system. In the first stage, the high pH water goes through a filter with a mixture of anthracite and fine sand, plus a gravel bed, removing any metal bearing particles. Liquid carbon dioxide is then added to the water. This typically reduces the pH of the solution to between 7.0 and 7.5, and it is run through another filter to target the removal of aluminum, which precipitates at a lower pH than other metals.

Finally, if necessary, a portion of the water is treated by reverse osmosis to reduce calcium and sulfate concentrations. Reverse osmosis is a process where water is pumped at high pressure through a membrane where water can pass through but larger ions like salts cannot. The resulting water is then monitored for pH and conductivity.

Interior of the Polishing Facility. The filters are on the right side, and the reverse osmosis equipment is on the left side.

Where does the water go after being treated?

Treated water is monitored to determine if it meets established water quality standards. Polished water meeting discharge standards is routed through a buried pipeline and is released into Silver Bow Creek. Treated water, not polished for discharge, is incorporated into the active mining operations. This process helps protect local water resources by reducing the amount of water the mine requires for active mining and by increasing the flow of natural creeks. Most importantly for the remedy, it ensures the Berkeley Pit water level remains below the protective water level.

Treated water being discharged into Silver Bow Creek near Montana Street.

Taming the Berkeley Pit by Dick Maney documents the construction of the Polishing Plant that was designed to filter mine water to a point that it could be safely discharged into Silver Bow Creek. The process, the construction, and the reasons for the Polishing Plant are explained in detail by the builders involved. The film reveals that by any standard this was a very large and complex undertaking.

Who is responsible for treating the water in the Berkeley Pit?

Atlantic Richfield Company and Montana Resources share responsibility for managing the Berkeley Pit and keeping water levels below the protective water level of 5,410 feet.

Who would be responsible for water treatment if Montana Resources closes permanently?

Both Montana Resources and Atlantic Richfield are responsible for keeping the Berkeley Pit water level (and other points of compliance) below the protective water level. Under the Superfund law, if one company is unable to pay its share, the other company must pay the remedial costs.